greenspecbusiness

Ozone generator

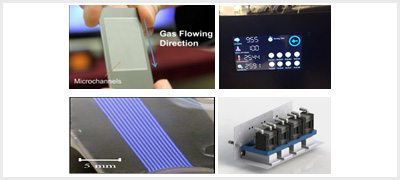

Micro-plasma Technology For efficient O3 production

I. Our Technology - Ozone production consists of ceramic line and aluminum electrode, ozone production using micro plasma

- - Manufacture of module-type device to meet customers' needs

- - Adjustable concentration and amount of O3(Display & Set)

- - Device price competitiveness (Longer lifetime)

- - Safety / Convenient Device Operation

- - Low energy consumption(Portable Unit is also available)

- - Remote control and monitoring possible

- More than 60 patents on microplasma technologythrough the University of Illinois

- Exclusive license from the University for water andair purification applications

II. Product Line as-is

-

1000 Series (0.3 – 2 g/h)

-

2000 and 3000 Series (3-30 g/h)

-

4000 Series (40-50 g/h)

-

5000 Series (80-200 g/h)

III. Challenges in Cooling Tower

- • Current problems

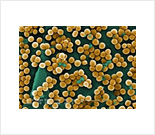

- • Microbial Growth (Bacteria, Algae)

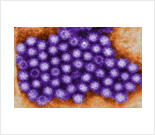

- • Waterborne Viruses (Legionella pneumophila)

- • Scaling in Pipes and Heat Exchangers

- • Organic Film Growth

- • Corrosion of Pipes and Heat Exchanger Units

-

Legionella

pneumophila -

Norovirus

-

Clostridium difficile

-

Hepatitis A

-

Adenovirus

-

MRSA

• Advantages of environment when using o3

- • Chemical reduction by 75 % to 100 %

- • Less blow down

- • Better heat transfer

- • Low energy consumption

- • Little maintenance & Green Technology& Green Technology

- • Less corrosion produced by bio-films & fouling

- • Prevention of Waterborne Diseases

• Advantages of economy when using o3

- • Saving Water Uses

- • No Anti-scaling and Anti-corrosion Agents

- • No Acid Addition

- • No Biocides ~ Storage and Transport Cost of Biocides

- • More Efficient Heat Transfer (Lower Energy Consumption)

- • No Environment Issue Related with Drain

- • Less Maintenance Labor

- • Health Safety For Maintenance Crew

• SPEC FOR O3 GENERATOR

| Cooling ton (m3/hr) | Water Flow Rate (GPM) | Injection method | The amount of 03 needed | Suggested equipment |

|---|---|---|---|---|

| 10 ~ 60 | 30 ~ 180 | Bubbling/Venturi | 5 -10 g/Hr | Options |

| 80 ~ 200 | 240 ~ 600 | Venturi | >20 g/Hr | Options |

| 240 ~ 500 | 720 ~ 1500 | Venturi | >30 g/Hr | Options |

| >600 | >1800 | Venturi | >40 g/Hr | Options |